Part two: Hydrometallurgy, chemical analysis and magnetic separation at SLR’s mineral processing laboratory

by Ben Simpson

View post

Firefighting foam has saved lives, but it has also left a toxic legacy that continues to impact people and the environment. At military bases, airports, and industrial sites, fire training grounds are now a common source of PFAS contamination.

This article shares four key lessons from assessing PFAS at a former Canadian military site lessons that apply to anyone managing foam legacy risks.

PFAS are a large group of industrial chemicals known for their resistance to heat, water and oil. They’ve been widely used since the 1950s in firefighting foams, industrial processes and consumer products. Their persistence in the environment has led to contamination of groundwater, surface water, drinking water, and soil around fire training areas.

Over 12,000 PFAS compounds have been identified, and their stability and persistence are what has earned them the nickname “forever chemicals”.

Major sources include locations where firefighting foam has been used, industrial sites that manufacture or apply PFAS containing products, wastewater treatment plants, and landfills.

If AFFF has been used at your site for training or emergency response, there may be a risk of PFAS migration toward groundwater, drainage features, or surface water. Regulators, water utilities, and communities are increasingly focused on identifying and managing these impacts. A proactive assessment can support informed decision-making and help minimize future regulatory or compliance risks.

Canada has started a national process to manage PFAS, with firefighting foam as one of the early focus areas, so foam use at industrial and defence sites is firmly on the radar.

Firefighting training areas are common on military bases, at airports and at industrial sites where large volumes of petroleum products are stored or handled. For many of these facilities, AFFF firefighting foam was used repeatedly over many years for live fire training and real incidents.

Every exercise and test added PFAS to the ground. Over time, this can lead to elevated PFAS concentrations in soil, shallow groundwater and nearby ditches or surface water.

Understanding PFAS loading is critical if you want to manage risk to receptors and plan realistic cleanup.

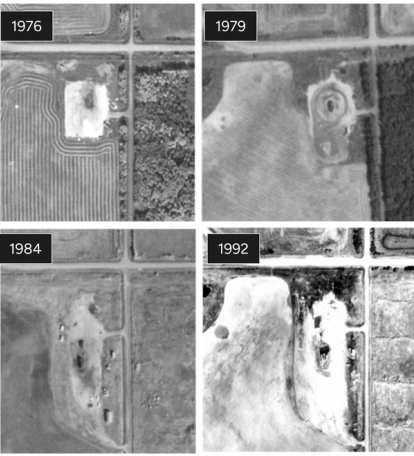

The military base in this case study has been operational since 1943. AFFFs were used for firefighting from the 1970s until 2018 for live fire training, emergency response, and in fire suppression systems.

Since AFFF was first flagged as a potential contaminant of concern at the site in 1999, several phases of work have been completed to understand PFAS contamination in soil, groundwater and surface water. This extended timeframe highlights the complexity of the site.

A few lessons from that journey are useful for any facility with a fire training area, whether that is on a military base, at an airport, or at an industrial or manufacturing site with its own firefighting personnel.

PFAS investigations stand or fall on basic site history

For owners and operators, the takeaway is simple: make time at the start to pull together fire training records, foam purchase and disposal records, as well as built drawings and historical imagery. It will save you time and money later.

PFAS moves with water. If you only sample once a year, you can miss how it behaves during periods of seasonal variation.

For industrial sites, this means that a one-off summer sampling round will not give a reliable picture of how your training area affects downgradient receptors over the whole year.

The conceptual site model (CSM) is the framework that ties all this together. It should change as you learn more. The following focus areas are recommended:

Industrial sites with training grounds or foam systems should ask:

If any of this sounds familiar, it is worth moving PFAS from the idea list to an active item on your risk register.

When it comes to industrial and manufacturing sites, a staged approach works best for PFAS investigation. Start with a desktop review and a simple conceptual site model for your fire training and foam use areas. Then design targeted soil, groundwater and surface water investigations, including seasonal work, so that each step tightens the picture before you commit to major remediation costs.

Assessing PFAS contamination at fire training areas is not just about sending a few samples to the lab. It requires a solid understanding of how your site has been used, a monitoring plan that captures key seasons and flow conditions, and a willingness to let your conceptual site model evolve as new data arrives.

At the case study site, that combination of history, seasonal PFAS sampling, careful data review, and regular CSM updates turned a broad concern about foam use into a clear picture of PFAS sources, pathways, and receptors. It also gave the client a realistic basis for planning soil and water management.

The same approach can be applied to airports, industrial facilities, and manufacturing plants that have relied on foam for training or emergency response.

If your facility has ever used foam for training or emergency response, now is the time to map your PFAS risk.

Our team has taken sites from first desktop review through detailed investigation, monitoring and remediation planning. Get in touch if you want a practical conversation about where to start on your site.

Get in touch